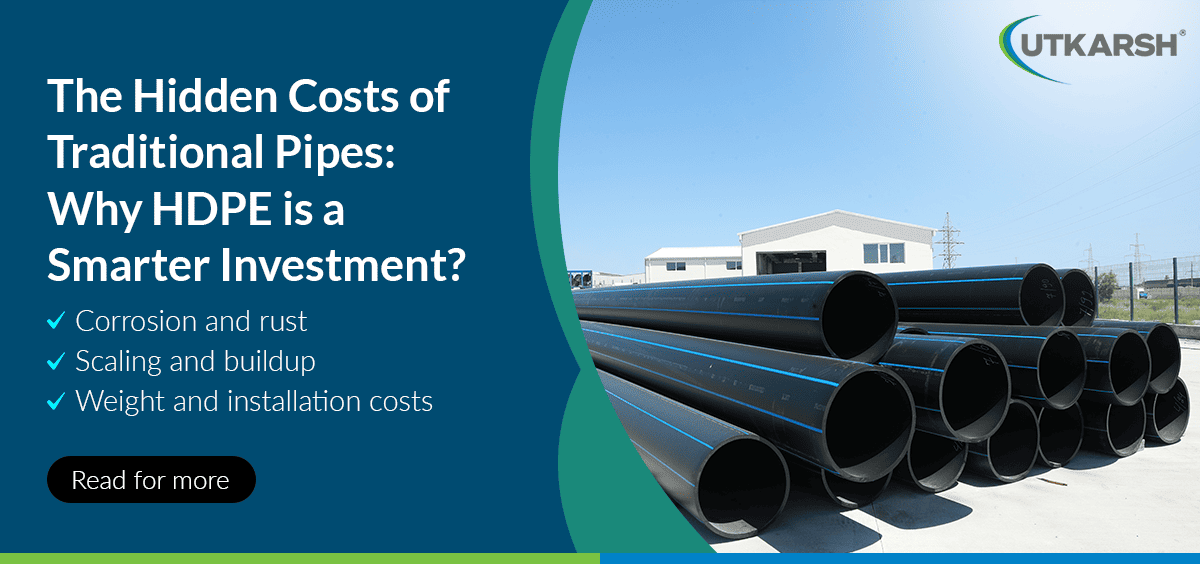

The hidden costs of traditional pipes: Why HDPE pipes are a smarter investment?

High-density polyethylene (HDPE) pipes are emerging as a compelling alternative to traditional metal pipes like steel or copper. While HDPE pipes might have a slightly higher initial cost, they offer substantial hidden cost savings in the long run. Let's explore some of the reasons why HDPE pipes are the wiser investment for your next plumbing project:

1. Corrosion and rust:

Metal pipes are vulnerable to rust and corrosion. Over time, exposure to moisture, chemicals, and environmental elements can cause significant degradation. This translates into leaks, cracks, and potential bursts in your pipes. Addressing these issues requires immediate repairs or even complete pipe replacements, incurring significant costs for both materials and labour.

HDPE pipes, on the other hand, are known for corrosion resistance. Their inherent material properties prevent rust and corrosion, ensuring they maintain their structural integrity for decades. This translates to minimal maintenance needs and eliminates the substantial expenses associated with frequent repairs and replacements that plague traditional metal pipes.

2. Scaling and buildup:

Other common issues that traditional pipes face include scaling and the deposit of minerals. This is especially true in regions that have hard water that is high in mineral content. Over time, scaling can restrict the normal water flow and reduce water pressure within the system. The blockages and clogs can get so severe that users may need to contact plumbers and get the deposits cleared. Such maintenance procedures can lead to significant additional expenses over the lifespan of the pipes.

HDPE pipes, on the other hand, have smooth inner surfaces that can resist scaling and deposits. This ensures that the water can flow through without any resistance. So, there is no need for frequent cleaning.

3. Weight and installation costs:

Metal pipes are considerably heavy and can be difficult to transport, which can increase the transportation expenses. Their weight also makes them difficult to handle during installation. This can lead to longer timelines for pipe installation and higher labour charges as a result. Besides that, workers may need safety equipment while handling such pipes.

HDPE pipes are significantly lighter in comparison, which results in minimal transportation and installation expenses.

Additional benefit: Environmental impact is another crucial factor to consider when choosing pipe materials. Traditional metal pipes have a larger carbon footprint compared to HDPE pipes. Also, disposing of used metal pipes at the end of their lifespan can pose environmental challenges.

HDPE pipes offer a more sustainable solution. Their production generally requires less energy and resources compared to metal pipes. Furthermore, HDPE pipes are made using recyclable materials. By choosing HDPE pipes, you're not just making a smart financial decision, you're also making a positive impact on the environment.

Looking for a reputed HDPE pipe manufacturer?

Explore our HDPE pipes. Our pipes are manufactured from virgin-grade raw materials and rigorously tested to ensure exceptional performance across diverse applications including potable water distribution, sewer systems, chemical transportation, irrigation systems, HVAC systems, and more. They are lightweight and easy to transport, thus, ensuring a smooth installation process. Their smooth inner surface minimises friction, resulting in a consistent C-value of 150 throughout their lifespan. Our HDPE pipes are built to withstand harsh conditions. They are crack-resistant, strong, weather-resistant, and offer excellent insulation properties. We do rigorous testing procedures, including stripe checks, visual inspections, melt flow rate analysis, density measurements, overall migration tests, and more. This ensures consistent quality and reliable performance.