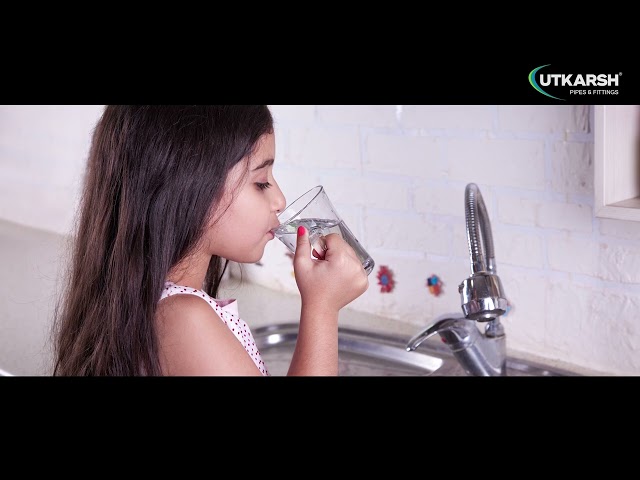

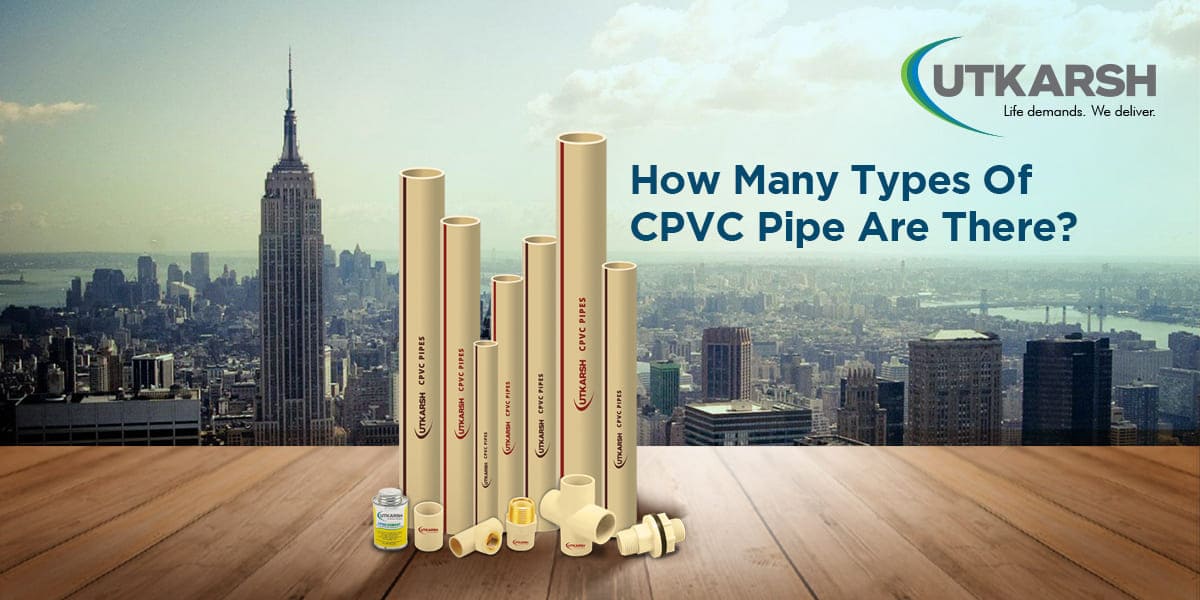

Chlorinated polyvinyl chloride (CPVC) plumbing pipes are the preferred choice worldwide for

both hot and cold potable water distribution systems. As India's leading CPVC pipes and

fittings manufacturer, we provide a wide range of CPVC pipes that ensure efficient and seamless

water supply systems. Our pipes offer enhanced durability, complete quality assurance, and

cost-effective operations, making them ideal for residential, commercial, and industrial

applications.

Crafted from carefully sourced raw materials, including premium CPVC resins from Japan, our pipes and fittings adhere to IS standards. Manufactured with state-of-the-art equipment, our products meet international quality benchmarks. With our commitment to providing the best quality solutions to our customers as a top CPVC pipe company in India, we ensure that each of our CPVC pipes and fittings meet the highest standards as per the global market.

Featuring top-notch specifications and properties, our CPVC pipes and fittings are tailored to meet the precise requirements of diverse applications and industries. With a maximum service temperature ranging from 82°C to 90°C, our CPVC pipes and fittings provide reliable performance. Rigorous water safety standards are followed, ensuring better usability for hot and cold water applications.

With decades of experience and technical expertise, we are proud to be the most trusted CPVC pipe fittings supplier in India and globally. Our unwavering commitment to quality and an ‘innovation-first approach’ enables us to consistently exceed customer expectations.

Crafted from carefully sourced raw materials, including premium CPVC resins from Japan, our pipes and fittings adhere to IS standards. Manufactured with state-of-the-art equipment, our products meet international quality benchmarks. With our commitment to providing the best quality solutions to our customers as a top CPVC pipe company in India, we ensure that each of our CPVC pipes and fittings meet the highest standards as per the global market.

Featuring top-notch specifications and properties, our CPVC pipes and fittings are tailored to meet the precise requirements of diverse applications and industries. With a maximum service temperature ranging from 82°C to 90°C, our CPVC pipes and fittings provide reliable performance. Rigorous water safety standards are followed, ensuring better usability for hot and cold water applications.

With decades of experience and technical expertise, we are proud to be the most trusted CPVC pipe fittings supplier in India and globally. Our unwavering commitment to quality and an ‘innovation-first approach’ enables us to consistently exceed customer expectations.

- Manufactured in Copper Tube Size (CTS)

- Made with meticulously selected, top-grade raw materials from international markets

- Rigorous 6-stage quality checks

- Suitable for hot and cold potable water distribution systems

-

44000

Plant Area

-

68000

Production Capacity

-

5000

Ready Stock

Product Specifications

Explore the detailed specifications of our CPVC pipes and fittings, ensuring high performance, durability, and compliance with international standards for diverse applications.

Read the technical specifications of our cPVC pipes and fittings, showcasing precise measurements, material quality, and performance parameters for reliable applications.

- Size range: SDR 11 & 13.5 - 1/2″ to 2" (Pipes); SDR 11 - 1/2″ to 2" (Fittings)

- ASTM D 2846 & ISI 15778 certified pipes and fittings

- Class 1 (SDR - 11), DN 15mm to 50mm; Class 2 (SDR - 13.5), DN 15 mm to 50mm

- Pipe and fittings standards ASTM D 2846 and IS 15778

- Length: 3 mtr

The world-class standard specifications of our CPVC pipes and fittings ensure that they meet key industry standards for consistent quality and dependable performance.

- Crafted from premium chlorinated polyvinyl chloride (CPVC) resins sourced from Japan.

- Class 1 pipes feature a red stripe; Class 2 pipes have a brown stripe.

- Designed to withstand maximum service temperatures ranging from 82°C to 90°C.

- Varying pressure ratings at any given temperature; Suitable for different applications in residential, commercial, and industrial sectors.

- Produced using state-of-the-art equipment, ensuring compliance with international standards.

Explore additional specifications of our CPVC pipes and fittings, covering essential details like installation ease, compatibility, and performance features for varied applications.

- Lightweight design ensures quick, hassle-free installation.

- Powerful chemical resistance, corrosion resistance and weather resistance.

- Quality assurance through 6 stages of testing

- Specially formulated to resist UV radiation; Robust construction of our CPVC pipes and fittings provides resistance to physical impacts.

- Hygienic, bacteria-proof, and no scaling risks

| Sizes Available | As Per Standards | |

|---|---|---|

| CPVC Pipes | SDR 11 & 13.5 - 1/2″ to 2" | IS 15778 |

| CPVC Fittings | SDR 11 - 1/2″ to 2" | ASTM D 2846 |

| Sizes Available | As Per Standards | |

|---|---|---|

| CPVC Pipes | Class 1 (SDR -11) |

15 to 50 (mm) ½ to 2 (inch) |

| Class 2 (SDR -13.5) |

15 to 50 (mm) ½ to 2 (inch) |

|

| CPVC Pipes | Effective length | |

| 3 mtr | ||

Product Fittings

As India’s leading CPVC pipe fittings manufacturers, we offer robust and high-quality fittings designed for reliable connections in various water supply systems.

Application Areas

Manufacturing Process

As a leading CPVC pipe company in India, a meticulous manufacturing process is followed for our range of cPVC pipes & fittings, right from raw material selection through final inspection and packaging.

-

Raw Material Preparation

The raw materials and chemicals are fed into a high-speed mixer using an automatic system, following a pre-set recipe. Once the mixture reaches the designated temperature, it is transferred to a cooling chamber until it cools to a predefined temperature, and then the compound is sent to the extruder hopper.

-

Feeding into Extruder

The cooled material is fed into the extruder via a hopper, utilising either a gravimetric or volumetric control system for precise measurement.

-

Heating and Melting

Inside the extruder barrel, the material is heated to its melting point of approximately 180°C. This heating is achieved through load (melt pressure) and friction generated within the twin-screw system.

-

Pipe Formation

The melted material is pushed through a die-head (spider), forming it into the shape of a pipe.

-

Calibration and Cooling

The pipe is calibrated to the correct size using a vacuum sizing tank and is subsequently cooled with water in a spray tank.

-

Cutting and Printing

At the end of the production line, the pipes are printed with necessary markings and cut to lengths based on intended use.

-

Quality Inspection and Dispatch

All pipes undergo online inspection and testing according to standards. After passing inspection, they are sent for final quality assurance checks before being dispatched as finished goods.