Related Blogs

Explore more with our related blogs on our products, manufacturing processes, solutions and more.

What makes HDPE Pipes better for Agriculture and Irrigation Application?

HDPE pipes are flexible plastic pipes that are mainly used for industrial and agricultural sectors to transfer fluid or gases. These are the perfect replacements for age old concrete or steel pipelines. Made from high-density polyethylene, these are highly impermeable. This quality makes it suitable for high pressure pipelines.

Applications

HDPE has multiple applications. They find use in water and gas mains, sewer mains, rural irrigation, fire system supply lines, drainage pipes and many more. These pipes can be melted, reformed which makes it rugged, flexible and long-lasting.

Features:

Due to some inherent features, HDPE pipes are best suited for agriculture and irrigation applications. The toughness and resistance to strong chemicals and their resistance to corrosion are some of its major features. They along with factors like low weight, cost-effectiveness and durability have contributed to its ever growing need.

HDPE pipes can be bent on site to a radius twenty-five times more than a normal pipe at or below 20 degree centigrade of ambient temperature. This feature leads to major cost savings. On the other hand, because of their high impact resistance and flexibility, they are suitable to be installed in soils that also include earth-quake prone areas. HDPE pipes ensure very high flow. Unlike ferrous piping solutions, these do not develop rust or corrode. Hence, these never affect the flow capabilities by building up internal resistance while fluids or water pass through them.

You May Like: Highlighting The Difference Between CPVC and UPVC Pipes

What makes them the perfect choice for agricultural and irrigation applications?

No piping fatigue: HDPE pipes are outstandingly fatigue resistant. Unlike plastic pipes, they are capable of handling the occasional and recurring surge of water flow that is very common in water distribution systems. These pipes are ductile but they are not rigid.

No water loss: HDPE pipes are leak-free joints. While other piping systems are highly susceptible to water leakage due to the types of joints that they use, HDPE pipes can be joined by heat. This results in permanent leak free joints that help us save our most precious resource.

Convenient installation: The flexibility of HDPE pipes, along with their tensile strength , makes the perfect choice for trenchless installation. This technology helps them in getting installed under the river, lakes, ponds, creeks with minimal public disruption.

High durability: HDPE pipes do not corrode or rust. This extends their life and results in long term cost savings. With a service of ranging from 50-100 years, HDPE pipes become the ideal solution depending on usage, installation and project design.

Environment –friendly: Apart from the above mentioned physical attributes, HDPE pipes have minimal impact on the environment. They do not emit hazardous levels of toxins even during the manufacturing process. Also, these can be easily recycled back into non-pressure piping applications.

The outstanding performance of HDPE pipes ensures that consumers get clean and safe potable water. While other pipes have high chances of having leaks that lead to more usage of electricity to process and pump water, HDPE ensures zero leak. This reduces the need for electricity which in turn helps the consumers in saving utility costs. These, together, make HDPE the ideal choice for agricultural and irrigation applications.

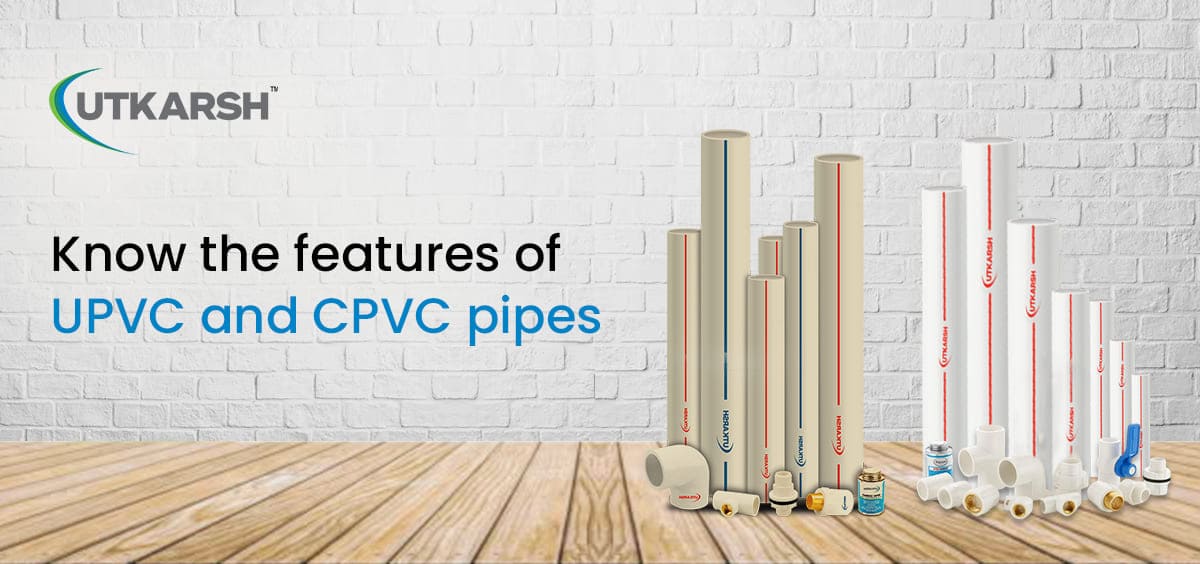

Highlighting The Difference Between CPVC and UPVC Pipes

Poly Vinyl Chloride (PVC) is one of the most widely produced and used synthetic polymers. Plasticizers are added during the manufacturing of PVC in order to make it easy to bend and to increase its flexibility.

Well, PVCs are also manufactured without plasticizers in order to make it rigid and sturdy. This material is known as UPVC. SometimesPVC is treated with chlorine using free radical chlorination in order to obtain PVC.

What is UPVC?

Unplasticised Polyvinyl Chloride, commonly referred to as UPVC other than its full form, is rigid PVC, lacking any plasticiser. Renowned for its resilience, UPVC stands as a tough, sinewy, transparent, and durable material, exhibiting resistance to atmospheric influences, moisture, and various chemicals. It boasts excellent electrical properties and low flammability. Globally, UPVC pipes and fittings are widely embraced, known for their inherent rigidity and resistance. UPVC pipes, recognised for their durability, fire-resistance, and recyclability, epitomize a reliable choice in diverse applications worldwide.

You May Like: What makes HDPE Pipes better for Agriculture and Irrigation Application?

What is CPVC?

Chlorinated Polyvinyl Chloride (CPVC) is manufactured by the chlorination of PVC polymer. Due to the chlorination, it acquires some unique properties like flexibility and the ability to withstand extreme temperatures. It is due to its chlorine content that it has excellent chemical resistance, primarily to acids, alkalis and salts, and is therefore ideal for the chemical process industry.

Application of UPVC Pipes

UPVC(Unplasticised Polyvinyl Chloride) pipes and fittings provide the perfectsolution for cold water applications across diverse sectors, includingresidential plumbing, swimming pools, industrial process lines, food andbeverage industries, saltwater lines, and the chemical sector. Utkarsh India’sUPVC pipes are rigorously tested through six stages of quality checks, ensuringboth reliability and high performance. This cost-effective, low-maintenanceproduct is especially suitable for domestic cold-water transportation systems.

Application of CPVC Pipes

Utkarsh India’sCPVC (Chlorinated Polyvinyl Chloride) pipes are versatile and ideal for variousapplications. They are perfect for both hot and cold water systems inresidential spaces such as homes, apartments, hotels, resorts, hospitals, andhigh-rise buildings, ensuring a pure and hygienic water supply. Additionally,CPVC pipes are well-suited for water mains in both domestic and industrial settings,as well as industrial water lines and plant piping. They offer excellentchemical resistance, making them suitable for use in industrial lines.

Difference between CPVC and UPVC

Delve into the CPVC vs UPVC comparison and gain valuable insights to make well-informed decisions tailored to your specific industrial applications and requirements.

| UPVC | CPVC |

| UPVC does not contain any plasticizers | CPVC is composed of plasticizers |

| UPVC is not bendable | CPVC is bendable |

| UPVC pipes are not suitable for carrying high-temperature liquids. | CPVC pipes are ideal for carrying high-temperature liquids |

| UPVC is not used for the purpose of drinking water transmission. | CPVC is suitable for the purpose of drinking water transmission. |

| UPVC is rigid | CPVC is flexible |

Final Note

PVC, a widely utilised material in pipeline production, comes in two distinct types: UPVC and CPVC. The critical difference lies in their composition, UPVC is made without plasticisers, while CPVC involves the addition of plasticisers and a chlorination process. When evaluating temperature resistance, CPVC surpasses UPVC in its ability to withstand higher temperatures. As a leading CPVC and UPVC pipe manufacturer in India, Utkarsh India stands out with their offerings.

Here are some top features of Utkarsh India's CPVC and UPVC pipes, aiding in the decision-making process for those who want to know:

CPVC pipes

· Corrosion-resistance

· Bacteria proof

· Chemical resistance

· Fire safety

· Leakproof

UPVC pipes

· Lead-free

· UV resistant

· Chemical resistant

· Waterproof

· Pressure resistant

Uses And Advantages of HDPE Pipes

High-density polyethylene is a thermoplastic polymer which is produced from the monomer ethylene. The high-density polyethylene pipe market is growing rapidly in India. As per many trusted reports, the HDPE pipe industry in India was at $99.9 million in 2018 and it is estimated to reach a staggering $233.5 million by 2026.

HDPE pipes are known for their high tensile strength, flexibility, durability and lightweight. These pipes have been used for municipal and industrial water applications for several years. The fact that HDPE pipes are environment friendly makes it even more favourable. These pipes are non-toxic, chemical and corrosion resistant, and ensure a long lifespan. The best quality HDPE pipes from top HDPEpipe manufacturers and suppliers ensure zero leak rate.

Here are some of the properties of HDPE pipes -

· HDPE pipes can resist many solvents, chemicals, and acidic environments

· HDPE pipes have high strength and flexibility and are much lighter in weight.

· These pipes are resistant to impact and that is what makes it a favourable choice for large industrial projects.

· Superior quality HDPE pipes from leading HDPE pipe manufacturers have a long life span of 50-100 years

Related: What makes HDPE Pipes better for Agriculture and Irrigation Application?

Advantages of HDPE pipes –

· Easy to handle and hassle-free to install – HDPEare easy to handle and install. Its density is way lesser than steel and does not demand any heavy lifting equipment during the time of installation. As these pipes are flexible, they can be bent easily.

· Minimized installation costs – These pipes require fewer fittings and can be welded into seamless leak-free pipe runs. This reduces the expense of labour and installation.

· Corrosion and chemical resistance – One of the finest quality of HDPE pipes is that it features chemical and corrosion resistance. It offers brilliant corrosion resistance to corrosive, acids, bases and salts and remains unaffected by fungi and bacteria.

· Heat-fused joints - HDPE pipes are heat fused to form a strong joint. This offers significant installation advantages when compared to traditional pipes.

Conclusion

At Utkarsh India, we are one of the leading HDPE pipe manufacturers and suppliers in the country. Our HDPE pipes have been tested and proven effective for aboveground, surface, buried and floating applications. Our HDPE pipes are popularly known for their applications in water supply, potable water distribution, sewage transportation, sprinkler irrigation systems and so on.

What makes our HDPE pipes an ideal solution are the standards that we maintain at Utkarsh India.

· IS 4984 - 2016 for Water Supply

· IS 4427 for Potable Water

· IS 14333 for Sewerage

· EN 12201 for Water Supply

· IS:14151 (Part I & II) for sprinkler irrigation systems

Everything You Need To Know About Submersible Pumps

A submersible pump, as the name suggests, is a kind of pump that can be fully submerged in water. It pushes the water to the surface by converting rotary energy into kinetic energy into pressure energy using. It does so with the help of a motor. The motor is hermetically sealed and close-coupled to the body of the pump.

One of the major advantages of submersible pumps is that it does not need to be primed because itis already submerged in the water. Also, these pumps operate very quietly as the water absorbs the noise. They are also more efficient as they do not require a lot of energy to suck in the water as they are submerged within.

There are a few disadvantages with submersible pumps as well. The seals of the pump can become corroded with time and when that happens, water seeps into the motor, making it useless. It must also be noted that these pumps are a bit difficult to repair.

Submersible tank pumps are designed to pump water upwards through the top of the roof. They are generally used in underground tanks where water needs to be pumped up to the roof surface.

Submersible pumps can be installed in above-ground tanks as well, however, you need to keep in mind that the rainwater will be plumbed in from the top. Also, if there is a need to directly access water from the tank, a tap can be installed or you can also choose to connect the rainwater to nearby taps.

It has to be made sure that the submersible pipe is fully submerged in the water because when the pipe is surrounded by water it helps it to cool the motor. If the pipe is out of the water, then it can overheat.

Some of the most common types of Submersible Pumps are –

· Bladder Pumps

· Well Pumps

· Borehole Pumps

· Grinder Pumps

· Fountain Pumps

· Utility Pumps

When properly maintained a submersible well pump can have along with with a lifespan of up to 15 years. It is also recommended to use the best submersible pipe for impeccable performance. At Utkarsh India, we are one of the leading manufacturers of Column Pipes that are ideal for the smooth functioning of submersible pipes. They are designed with square threads to provide smooth fitment /re-fitment.

What Are The Different Applications And Benefits of UPVC Pipes and Fittings?

The term UPVC stands for Un-plasticized Polyvinyl Chloride which shows strong resistance to chemicals and harmful elements of nature. UPVC pipelines are ideal for solving the plumbing needs of commercial and residential properties.

As metal pipes react with several elements of nature, these are not suitable for plumbing applications. These pipes are prone to rust and corrosion. That is why; the supplied water remains safe from impurities wherever a UPVC pipeline system is installed.

Seamless the flow of clean and safe water is a necessity irrespective of the region and the type of properties. The industry has been experimenting with different materials to find the most suitable raw material that ensures a safe water supply.

The invention of UPVC pipes has revolutionized the plumbing industry bringing solutions to several issues associated with metal pipelines. Let us explore UPVC pipe’s various applications and benefits to understand the immense significance it carries across the plumbing industry.

Applications of UPVC pipelines:

· UPVC pipes are used to fulfill plumbing needs across water supply systems. Besides, these are used for Tubework casting and manufacturing raising mains for hand pumps as well.

· In chemical industries, it is used for transporting chloride and other chemicals.

· UPVC is used as ventilation pipes for disposing of corrosive gases from washrooms.

· In the electric industry, UPVC is used for manufacturing electrical conduits.

· For agricultural purposes, it has extensive use in irrigation.

· The crude oil pipeline is made of UPVC as well as it prevents corrosion within the pipeline.

· The sewer system is manufactured out of UPVC pipes too.

Related Blog: Difference Between CPVC and UPVC Pipes

Benefits of UPVC pipelines:

· As a material, UPVCs are very lightweight. Hence, a low amount of shipping and labor charges are required to transport.

· UPVC pipes are budget-friendly and can be installed following a hassle-free process.

· These pipes have anti-corrosion properties which resist chemicals to react with the material. As a result, the water or gas remains unchanged inside the pipeline.

· Due to low thermal conductivity, UPVCs are highly energy efficient. It has flame retardant properties that do not support combustion.

· UPVC pipes are UV resistant, hence can be easily installed outside the building without worrying about the outcomes.

· They are completely eco-friendly and can function both in extreme cold and hot temperatures.

· Being antimicrobial, these are completely safe to carry drinking water as well.

UPVC pipes come with multiple benefits in various applications. They are not only cost-effective but also last longer than any other pipeline materials. These pipes neither need high maintenance nor require a complicated installation process. As UPVC pipelines come with a package of benefits across different application areas, these are preferred by industry professionals worldwide.

Factors To Consider When Looking For HDPE Pipes

High-Density Polyethylene pipes or HDPE pipes and fittings are widely preferred for a plethora of industrial applications. They are recognized for their strength, durability, chemical and corrosion resistance, and minimal leak rate. These pipes are used in a number of applications which include pipeline rehabilitation, sewer piping systems, slip lining, and geothermal applications among others.

When it comes to choosing the best HDPE pipes manufacturers in India, it is quite a difficult task as there are so many of them. Choosing the best out of it for your needs is a complicated and time-taking deal.

Here we have listed some of the factors that you need to consider while choosing the best HDPE pipe manufacturer or supplier.

Let’s take a look.

Understand your purpose – HDPE pipes are used for several purposes and so before looking for a manufacturer or supplier, you should know exactly where you want to use them. You should also know what dimensions you need and the number of pipes you need for your purpose.

Understand the product and its market – You must be well-informed about the market and keep an eye on the changes and updates taking place in the market. You should also understand the technology that is used to manufacture HDPE pipes and how that technology is evolving. This will help you to grab the best deal in the market.

Related Blog: Uses And Advantages of HDPE Pipes

Market reputation– Needless to mention, reputation is something that defines the image of a company. When it comes to choosing an HDPE pipe manufacturer in India, the experience and the reliability of the manufacturer matter a lot. You must check the experience of the manufacturer and also check their online comments, reviews, and website to get a rough idea of what their past customers think about the quality of their products and services.

The manufacturing process and other qualities – The manufacturing process and a few other factors determine the quality of the final product. Qualities like high productivity, use of advanced technology, the cost-effectiveness of the product, and customer service largely matters.

Conclusion

These are some of the factors which you must consider while purchasing HDPE pipes. However, if you are planning to purchase HDPE pipes from leading HDPE pipes manufacturers in India, Utkarsh India has got you covered.

We are a leading manufacturer and supplier of high-end engineering products and services in the infrastructure, agriculture, and domestic water piping industry. Coming to HDPE pipes, Utkarsh India’s HDPEpipes have been tested and proven effective for above ground, surface, buried, floating applications. It ensures a lifespan of 50-100 years and is certified by the Bureau of Indian Standards.

How Are PVC Pipe Fittings Made?

PVC as a material

Also known as PolyvinylChloride, PVC is one of the most common thermoplastic polymers used all over the world. It is naturally white and very fragile plastic before the addition of plasticizers. PVC is generally produced in two forms a rigid or unplasticized polymer and another as a flexible plastic. Industries such as plumbing, water supply, sewage, and agriculture utilize rigid PVC across different functions. Flexible PVC is commonly used for construction purposes to provide insulation on electrical wires or in flooring for homes, hospitals, schools, and in other sterile areas where the environment is a priority.

Characteristics of PVC

Some of the significant properties of PVC are:

- Density - PVC has a specific gravity of around 1.4 and is considered to be the densest plastic.

- Economics – PVC is cheap and readily available in the markets.

- Strength – PVC possesses excellent ductile strength.

- Hardness – PVC in rigid form grades well for hardness and durability

PVC pipes are one of the most universal and versatile types of plastic piping, serving a multitude of applications in various market sectors all around the world. PVC pipes are extremely strong and durable when compared with other piping materials and also prevent corrosion which makes them the ultimate choice for water supply and a manifest for the sewer system in big cities around the world. Economical and robust, these pipes come in various sizes with a wide range of available pipe fittings that are used for both warm and cold-water applications conditional to different types of PVCvariants.

How are PVC Pipes made?

PVC pipes are made by extrusion of raw material PVC, and thereby following the same step of typical pipe extrusion the process mentioned below :

- Feeding of raw material tablets / powdered into the PVC twin screw extruder.

- Melting and heating in numerous extruder zones.

- Extruding further to shape into a pipe.

- Cooling the shaped pipe.

- Finally, cutting the PVC pipes to the desired length.

These are a similar manufacturing procedure for most plastic piping; however, PVC pipes have fundamental features that possess additional characteristics and challenges to pipe manufacturers both in terms of production and market positioning of their products.

Related: Highlighting The Difference Between CPVC and UPVC Pipes

PVC fittings are made from a material known as Polyvinyl Chloride. PVC fittings are manufactured by heating plastic pitches and the molten pitches are set to create desired shapes and sizes. The PVC fittings and pipes are widely used for various reasons like irrigation purposes, building, construction, water supply, sewage management, and many other modes for a requirement.

Description and Application of PVC Fittings

Below is a list of the most commonly used PVC fittings available as follows:

- PVC fittings used as Tees – PVC tees are three-end fitting; it allows a link to be split into two separate lines with a 90-degree connection. They are popularly used for PVC structures.

- PVC fittings used as Elbows – PVC elbows are available in 90-degree angles and 45-degree angles. These are used for redirecting pipelines by bending them into the desired directions.

- PVC fittings used as Crosses – PVC crosses are fittings that are used for connecting four sections of the pipe. They have four slip connection that meets at 90-degree angles forming a plus shape.

These are the description and applications of the three most commonly used PVC Fittings in the markets.

For more information regarding PVC fittings and pipes, contact Utkarsh India Limited a leading manufacturer and supplier of high-end engineering products and services in the infrastructure, agriculture, and domestic water piping industry at https://utkarshindia.in/.

Best Quality PVC Casing Pipe for Domestic Borewell

Polyvinyl chloride pipes also known as PVC pipes have become the ultimate choice for borewell. We at Utkarsh India Limited as being one of the leaders in the pipe manufacturing industry provides our customer with a variety of range of PVC casing pipes such as casing medium, casing shallow, and casing deep pipes as per the requirement of the customer in different depth of borewell developments. Considered among the best PVC casing pipes for borewells, we produce PVC casing pipes that have high superiority threaded joints and have anti-corrosive properties.

Why should you choose PVC casing pipes for domestic borewells?

Perfect for various Plumbing applications – PVC casing pipes can be used for various plumbing purposes because they can easily maintain the hydrostatic collapse pressure, hence making them an ideal choice for borewell projects. These pipes also can withstand changing water pressure and harsh weather conditions. It is ideal for irrigation, domestic and industrial applications, the PVC casing pipes for domestic borewell are a better alternative to cement, asbestos, and SS pipes. In addition to that these pipes are resistant to corrosion from violent chemicals present in the soil.

Acts as an Insulator - PVC casing pipes are non-conductive to electricity, hence eliminating the chance of electrochemical reactions. Further to that these pipes provide good resistance to chemicals and are immune to electrolytic and galvanic erosion. These pipes are safe to be applied to alkaline, acidic, dry, or wet conditions without any requirement for protective coating.

Superior durability – Unlike conventional metal pipes, PVC casing pipes are corrosion resistant. In addition to that best quality PVC casing pipes do not react to harsh industrial chemicals. Hence PVC casing pipes last longer than metal casing pipes. Their reliability and durability have made them the ultimate choice for all borewell developments. Following that PVC casing pipes are versatile as well.

User Friendly – Installation and Usertransportation are the main matter of discussion when it comes to choosing the best PVC casing pipes for borewell projects. PVC casing pipes have considerably less weight when compared to metal pipes or metal piping materials. This helps with easy transportation and better installation of PVC casing pipes without much hassle. PVC casing pipes come in various ranges which provides the customer with an advantage to fulfill their requirements following their borewell project. The lightweight PVC casing pipes ensure lowering the cost of installation, maintenance, shipping, and labor.

At Utkarsh India Limited, we offer our customers a wide range of PVC casing pipes that fulfill all the above features from being user-friendly, durable, non-conductive to being the perfect material for various Plumbing applications. Our PVC casing pipes come in various dimensions that meets all the chemical properties as per different testing results such as density test, resistance to external blow at zero-degree Contest, effect on the water test, Vicat softening temperature test, and tensile strength test.

For more information regarding PVC casing pipes, contact Utkarsh India Limited a leading manufacturer and supplier of high-end engineering products and services in the infrastructure, agriculture, and domestic water piping industry at https://utkarshindia.in/.

How Many Types Of CPVC Pipe Are There?

The piping industry is highly undervalued. The quality, safety, and performance provided by such an industry help to play a crucial part in safeguarding the environment along with the lives of people. CPVC pipes and Fittings produced by Utkarsh India, one of the premier CPVC pipes manufacturers in India; are manufactured using high-quality plasticizers, which helps the pipes with utmost rigidity and provides sturdiness.

What is CPVC?

CPVC is also known as Chlorinated Polyvinyl Chloride, is manufactured by the chlorination of PVC polymer. The chlorination helps the pipes to attain some unique qualities like ductility and they are also able to withstand extreme temperatures. As chlorine has excellent properties of chemical resistance primarily to acids, alkali, and salts, hence CPVC pipes became an ideal choice for chemical process industries.

Features provided by CPVC pipes and Fittings of Utkarsh’s

CPVC pipes and Fittings are known for their ability to withstand extreme physical and chemical degradation. Some of their features include.

• Corrosion resistant.

• Bacteria resistant and chemical resistant

• Leakage-proof.

• High mechanical strength.

• Easily installable and have a low maintenance cost.

• Ideal for drinking water supply.

• Great insulation properties.

• Economical and cost-effective.

• Durable and long-lasting.

Types of CPVC Pipe and Fittings

CPVC pipes and fittings are available in different classes and grades all over India:

SDR 11 Pipe:

• IS Standard – IS 5778 ASTM D 2846

• Sizes available – ½†- 2

• Description – They are widely known as class 1 pipes and are heavier when compared to SRD 13.5.

SRD 13.5 Pipe:

• IS Standard – IS 5778 ASTM D 2846

• Sizes available – ½†- 2

• Description – They are widely known as class 1 pipes and are lighter when compared to SRD 11.

Sch. 40 Pipe:

• IS Standard – ASTM F 441

• Sizes available – 2.5†– 6â€

• Description – They are widely used for domestic water supply purposes.

Sch. 80 Pipe:

• IS Standard – ASTM F 441

• Sizes available – 2.5†– 4â€

• Description – They are widely used for industrial purposes.

List of CPVC fittings as follows:

Sch. 40 Fittings:

• IS Standard – ASTM F 438

• Sizes available – 21/2†– 6â€.

Sch. 80 Fittings:

• IS Standard – ASTM F 439

• Sizes available – 21/2†– 4â€.

SDR 11 Fittings:

• IS Standard – ASTM D 2846

• Sizes available – ½†– 2â€.

This; is the list of CPVC pipes and Fittings that are available in the particular classes and grades in India.

Ending note

CPVC or Chlorinated Polyvinyl Chloride is a material that is widely used in the production of pipelines. Here in this blog, Utkarsh India, a premier CPVC pipe manufacturer in India, has provided you with numerous types of CPVC pipes and Fittings along with their sizes and IS standards. We have also provided information regarding the major features of CPVC pipes and fittings. We hope that you find this information helpful.

For any further clarification or questions, please contact us at info@utkarshindia.in or visit us at https://utkarshindia.in/.

Agricultural Applications Of PVC Pipes

Before we turn to the details of the use of PVC pipes in the agricultural industry, let's first recall that India ranks second worldwide in agriculture production, is the world's largest producer of fresh fruits and vegetables, and ranks second in wheat and rice production. All these facts prove that agriculture is of paramount importance in the country as it generates nearly 16 percent of the GDP. Thus, much of the infrastructure and equipment in the agriculture sector is crucial to its efficient functioning.

The agricultural sector relies heavily on drainage and irrigation channels made of PVC pipes and fittings. Rigidly built PVC pipes are essential when the soil is deficient in absorption capacity or when water levels are high due to salinity levels on the land. This is because PVC pipes have a smooth lining that ensures water travels smoothly to its intended destination with a minimum of clogging as compared to pipes made out of similar materials like copper and clay.

With all of that in mind, let us move straight to the core of this blog.

Use of PVC Pipes in Agricultural Industry

Below are just some of the ways to use PVC pipes in your agricultural facility:

PVC Sprinklers

Large-scale water supply systems rely heavily on PVC pipes. They can be mounted aboveground and linked to the main water source and sprinklers. When buried as deep as 10", ¾†PVC pipes make excellent irrigation laterals.

Drip Irrigation

A popular watering method, drip irrigation involves punching holes through the hose to control the flow of water. Its popularity stems from the fact that it provides sustainability to your agricultural facility by conserving water. This framework is perfect for little-to-medium-sized gardens and enables each plant inside that region to get an unfaltering stock of water delivered to the roots. Using PVC pipes in this system is feasible because they're flexible, so they won't tear once they've been punctured.

You May Like: Best Quality PVC Casing Pipe for Domestic Borewell

Vertical Garden

There are various ways of forming a vertical garden using different sizes of PVC pipes. A small PVC pipe with an irrigation line is inserted inside a larger PVC pipe with the pot of soil and the plants.

Hydroponic garden

Water is supplemented with nutrients to support seedling growth in hydroponic gardens. It is also referred to as an active system and is a type of hydroponic farming that reliably produces more while conserving water. PVC pipes hold plants in mid-air, and water containing nutrients flow through the pipes continuously. Since PVC pipes are lightweight and lack toxicity, they are apt for this system.

You May Like: What makes HDPE Pipes better for Agriculture and Irrigation Application?

Final words

Many agriculture facilities utilize agriculture PVC pipes and fittings as water delivery systems. Their corrosion resistance and ability to stabilize UV rays make them an ideal choice for any farming operation. PVC pipes play a crucial role in large-scale agricultural facilities because they make irrigation more sustainable and efficient. Small agricultural spaces or even home gardens can be irrigated using PVC pipes.

Primary Differences Between PVC And CPVC Pipes

PVC (Polyvinyl Chloride) pipe is widely used for the purpose of supplying water in irrigation, drainage of soil & waste in buildings, conduits for electrical wires & industrial chemical transportation. In some cases, PVC pipes are also used as water supply pipes in buildings.

CPVC (Chlorinated Polyvinyl Chloride) pipe has been used extensively in fire sprinkler systems since 1985. This material is also used for many industrial and process piping applications as it is corrosion-resistant, easy to install, has superior mechanical strength and long service life.

To start with, the primary difference between CPVC and PVC pipes is the range of temperatures each is capable of resisting. CPVC can handle temperatures up to 200° Fahrenheit, while PVC can maximum go up to 140° Fahrenheit. If the temperature exceeds what’s mentioned, both CPVC and PVC will begin to soften, increasing the risk of joints and pipes failing, and therefore lead to a failure of the plumbing system.

You May Like: Agricultural Applications Of PVC Pipes

• PVC and CPVC are inherently inert to most acids, bases and salts, as well as aliphatic hydrocarbons. This can extend their service life often for years or decades longer. Chemical resistance is a clear advantage for both CPVC and PVC. Though, it must also be noted that there is a difference in sulfuric content in both the materials and that makes CPVC slightly superior to PVC.

• CPVC and PVC pipes have the same pressure rating at 73°F (22.8°C), but it must be noted that as the temperature increases, CPVC maintains its pressure rating better than PVC. While PVC can still be used for applications with pressure at 130°F (54.4°C), the material can withstand significantly less pressure at high temperatures (above 73°F) than CPVC.

You May Like: The Difference Between CPVC and UPVC Pipes

We hope that this article has helped you to understand the differences between PVC and CPVC pipes. With that being said, Utkarsh India is one of the leading CPVC and PVC pipe manufacturers in India with over decades of experience in the piping industry and we are highly respected in the government as well as infrastructure sector for our passion and commitment to contribute in the process of nation-building. We also source our raw materials from some of the leading producers.

So if you are looking for superior quality CPVC pipes or PVC pipes in India, we at Utkarsh India have got you absolutely covered. Our CPVC pipes and PVC pipes undergoes various tests which the Tensile Strength Test well to ensure their toughness, strength and rigidness.

Benefits Of Using SWR Pipes and Fittings

service, especially on SWR Pipes and Fittings. SWR pipes are chemical and bacterial resistant because of their high tensile and durability, making them suitable for waste removal. In comparison to conventional metal pipes, these pipes are popular in both residential and business settings. SWR is an acronym for 'Soil, Waste and Rain'. Soil, trash, and rainwater management all benefit from the usage of SWR pipes. Bacteria, fungus, microorganisms, rodents, and insects have no chance of infecting these pipes.

In a plumbing system, pipe fittings, also known as pipe connectors, join two or more pipes together to extend the run's length or alter the flow direction. Depending on the size of the pipe SWR pipe manufacturer join, they exist in a range of shapes and sizes for combining, diverting, or reducing water supply flow.

But to understand the reason why our SWR Pipes and Fittings are so popular, you need to understand the benefits of the same:

SWR pipes offer outstanding chemical, fire, and corrosion resistance characteristics. They do not rust or corrode as time passes, as opposed to other materials. Aside from that, the non-flammable characteristics of SWR pipes make them an obvious option for the transportation of chemical bi-products and hazardous chemicals and industrial hot waste.

Installation is a breeze because of the system's low weight and unique rubber jointing methods. Installing the pipes may be done entirely by hand by the operator of the pipes, with no risk of harm to themselves. They can be delivered easily in large numbers to remote locations cheaply since the pipes are so light and small. All spaces may benefit from the installation of these pipes since they are appropriate and acceptable in size.

When compared to alternative piping systems, SWR pipes save on installation, maintenance, and capital costs. As a result, the lightweight pipes are simple to install, lowering the costs of installation, handling, and shipping. Furthermore, because of the endurance of SWR pipes, it is more efficient than other materials, making it more cost-effective.

You May Like: Here Are Some Tips To Help You Choose The Best Pipe Suppliers

The inner surface of pipes and fittings must be mirror-smooth and restriction-free to provide better flow characteristics and prevent clogging and drain choke-up in the system. A high level of cleanliness is maintained throughout the system, which is completely leak-proof.

One of the primary benefits of SWR pipes is that they have high tensile strength, making them both dependable and durable. Because of the robustness of these pipes, they are a suitable option for sewage and drainage systems in industrial, residential, and commercial environments.

You wouldn't want to construct a whole piping system on pipes that aren't robust and can't hold up under pressure for an extended period, would you? A resounding "NO" is the response. Because of the great tensile and impact strength provided by the SWR Pipes and Fittings, ensured by the SWR pipe manufacturer, the whole plumbing system is very robust, strong, and durable.

Non-pressure plumbing applications need SWR pipes and fittings, which vary from pipes used for water drilling underground. They're perfect for transporting soil, trash, and rainfall in residential and business buildings, including hotels, resorts, and hospitals. They're ideal for industrial drainage and waste discharge systems that don't need pressure.

Utkarsh India’s SWR pipes and fittings are manufactured to the strictest of industry standards to ensure complete customer satisfaction. Our broad selection of UV stabilized SWR drainage and sewage pipes are perfect for outdoor use because of its visual appeal. The pipes' high tensile strength enhances durability and efficiency.

How Are PVC Pipes And Fittings Connected?

Despite the fact that you are already aware of how simple it is to construct a building out of PVC pipe, there is one critical step involved in ensuring that your construction is strong, long-lasting, and secure - and this step is equally simple - and that is linking everything together. It is critical to understand the proper method of connecting PVC pipes. You can do the work quite fast if you know what you are doing.

Here are some easy steps to follow for connecting PVC pipe and fittings:

Adhesives for PVC Pipe and Tube

PVC pipes and fittings don't need any adhesives to join them together. They won't be utterly impervious to water, though. You need to make sure there are no leaks as the liquid would be flowing through those pipes. This may be accomplished in several ways, and the one you select will be determined by what you want to link.

You Know More- How Are PVC Pipe Fittings Made?

The ends of the PVC pipe are seldom threaded. Slip ends are joint on PVC fittings for a variety of reasons. While "slip" implies a slippery connection with PVC, it means the fitting will slide directly on top of the pipe. Even if the connection between a pipe and a slip fitting seems tight, it must be sealed to transmit liquid media. PVC cement binds plastic parts together to form a watertight seal on pipes. PVC primer and PVC cement are required for a reliable seal on a slip fitting. The primer prepares the fittings inside for bonding while the cement ensures that the two parts remain firmly attached.

It is necessary to seal threaded fittings differently. Threaded components are popular because they allow for easy disassembly. PVC cement forms a seal in threaded connections but damages the threads because it binds the pipe together. PTFE thread seal tape works well for sealing threaded connections and keeping them operational. To maintain the connection sealed and lubricated, just wrap it around the male threads a few times. The fittings will still unscrew if you need to return to that junction for repair.

You May Like- Best Quality PVC Casing Pipe for Domestic Borewell

Fixtures for joining PVC piping and fittings

Fasteners (screws) may be used to temporarily provide a solid structural hold to PVC pipe and fittings while keeping them secure without using PVC cement. The fittings may then be reused or repositioned at a later time. There are some limits to this technique. It isn't as firm as PVC cement, and it won't work for internal-fit components like couplings and dome caps because of the way they are designed to be connected.

Here's how you use fasteners to join PVC pipes together-

The fitting should be inserted into the pipe. Use a mallet if required to ensure it is thoroughly entered and that it is firmly seated. Into the fitting's side, drill a pilot hole approximately halfway between the pipe and the fitting. The screw will go in much more easily now. Using your drill or driver, drill a pilot hole and then put a self-tapping screw into it. If the screw is too short, the fitting and pipe will not fit.

Both of the techniques described above will help you build a solid PVC construction that you may use for many years to come. Even if none of the above techniques appeal to you, you may just press the pipe and fittings together until they stay attached. However, this method can result in parts that are too loose owing to manufacturing variations. Using the fastener connection approach to attach any loose parts is highly recommended if this is the case.

All You Need To Know About HDPE Pipes

Synthetic petroleum polymers, such as HDPE, are utilized in the manufacturing of plastic bottles and water pipes and corrosion-resistant pipework. HDPE pipes have an average lifespan of more than 50 years because of their high density and huge strength. A lot of regular items are made of high-density polyethylene, such as containers, bottles, helmets, toys, and cosmetics. HDPE's non-toxic, odorless, and insipid qualities have made it a popular choice across the globe.

There are several applications for HDPE pipes in the household, fishing industry, agricultural business, and the chemical products industry, among many others. Learn about HDPE pipes characteristics and advantages before searching for the best one. Taking a deeper look at the benefits and aspects of HDPE pipe, let's look at the advantages and features.

Polyethylene (HDPE) pipes are ideal for high-volume applications:

HDPE pipes are well-suited for big-volume projects because of their long-term durability and strong temperature, chemical, and impact resistance. When it comes to fire system supply lines, water, sewage, and gas mains, as well as electrical and communication cables, HDPE pipes are a clear choice.

Tough and powerful:

It is possible to sustain dynamic and static stresses with the HDPE pipes because of their excellent impact resistance. When exposed to cold temperatures, these pipes will not fracture or break. HDPE pipes can withstand harsh handling and heavy traffic loads with ease.

HDPE fittings come in more than a dozen distinct types since they are employed in a variety of applications. Because HDPE fittings are widely available, they would be available regardless of the location of the project.

Passive to chemicals:

When it comes to handling corrosive acids and alkalis, HDPE pipes are a good choice because of their strong chemical resistance. Due to the fact that these pipes are chemically neutral, they are often used in chemical factories.

Flexible:

HDPE pipes and ducts are exceptionally flexible and can be bent without breaking, making them ideal for a wide range of applications. HDPE pipes have a fundamental characteristic that makes it possible to carry vast lengths of small diameter pipes in the form of coils.

Resistance towards electricity:

HDPE pipes have high dielectric strength, making them ideal for use as electrical conduits. In addition, there are no stray electrical currents that may be passed from outside the building.

Also You May Like: Uses And Advantages of HDPE Pipes

HDPE pipes and fittings are very durable and seldom need to be serviced or replaced. HDPE pipes and fittings have the lowest annual repair rate of any other pipeline material as a bonus to its many other advantages. Polyethylene is known for its toughness, solidity, and durability, so this shouldn't come as a surprise.

HDPE pipes and fittings will meet all of your needs, regardless of whether you are looking for long-term service, simplicity of installation, flexibility, chemical resistance, or environmental sustainability.

HDPE pipes and fittings will have a long-term influence on your project if you choose wisely. Therefore, you should only buy these pipes from a well-known manufacturing firm that has been in business for many years and has satisfied customers.

PVC Pipes Fittings - What Is It and How Is It Made?

PVC pipes or Polyvinyl Chloride pipes are popular applications in sewage pipes and main water lines. These pipes have replaced pipes due to their innumerable benefits such as being easy to install, lightweight and durable. This makes them cost-efficient, long-lasting, and sustainable water pipes.

PVC is a thermoplastic material that can be molded into any shape and design. These pipes are recyclable and do not produce any toxic chemicals. PVC pipes are the right fit for water transportation and drainage solution.

What Is Polyvinyl Chloride Pipes (PVC) ?

Polyvinyl is a man-made plastic in which additives and stabilizers are added to get the desired quality from the polymer. This polyvinyl polymer is then converted into the form of pipes better known as PVC pipes. PVC pipes are in use since the 1950s. Today, more than 2 million PVC pipes are in service.

PVC is resistant to oxidation and corrosion. The PVC pipes are highly durable, they can last more than 50 years when installed properly. During improper installation, the solvent joints or tree joints get burrowed into the way of pipe’s connection leading to damage of pipe and failure in durability.

How are PVC Pipes Made?

1. When the PVC pipes are made, these are the main steps that are followed.

2. A PVC twin-screw extruder is used to feed raw materials powder/ pellets.

3. Heating and melting are performed in several extruder zones.

4. Then it is shaped in the form of a pipe with the help of a die extruder.

5. The shaped pipe is then cooled.

6. Different PVC pipes are cut according to the needs.

Related: How Are PVC Pipe Fittings Made?

PVC Pipes Uses :

Water Supply

The PVC pipes are lightweight, durable, strong, and low reactive. These properties make them an ideal choice for water distribution applications. The PVC pipe fittings have a maximum threshold temperature thats why used hot water lines.

Drainage

PVC pipes are resistant to wear-tear and rust. They are also leak-resistant and have the ability for under loading without breaking apart. This is why PVC pipes are widely used in sanitary applications and underground plumbing.

Chemical Industry

The PVC pipes are resistant to seawater, alkalis, salts, and acids. It is widely used in the chemical industry for transporting hazardous chemicals.

What Are The Advantages Of Using PVC Pipes Fittings?

1. PVC Pipes offer very little friction to the flowing liquids. Also, the smooth surface of the pipes makes it a good choice to supply different liquids and is used in an array of industries.

2. Its lightweight nature helps in the process of transportation. This saves valuable money and time.

3. Highly pocket-friendly and readily available.

There are different sizes of PVC pipes available. Utkarsh India has the best quality product that meets your needs, and most prominently, fits your pocket. Utkarsh pipes have state-of-the-art technology and employ the latest technology to make high-performance products. Also, the products available are known to meet the national and international quality standards.

Plastic Plumbing Pipes - Why Are They Better Than Metal Pipes?

When you are planning a plumbing project the first and foremost concern is choosing the material for pipes. You will come to cross both metal and plastic pipes. In the last few years, most of the projects are shifting from metal pipes to plastic pipes and the common reason is PVC pipes fittings have numerous advantages.

Plastic pipes are polymer pipes, better known as PVC, CPVC and HDPE pipes which are popular over metal pipes and there are enough reasons to support this.

Polyvinyl chloride or PVC is a combination of plastic polymer and vinyl. This is the most common plastic pipe which is mostly used for residential purposes. The other common plastic pipes are chlorinated polyvinyl chloride (CPVC), and Polyethylene-raised temperature (PERT). These pipes are cost-efficient, durable, and safer than metal pipes.

You May Like: Uses And Advantages of HDPE Pipes

Advantages Of Plastic Plumbing Pipes :

Safety

Plastic pipes are a better choice for the transportation of clean drinking water. Plastic pipes have resistance to corrosion and inert bio-film protection to prevent the inhibition of the growth of bacteria. Moreover, pipe leakage accidents are not new but with plastic pipes, it is easy to mold and repair.

All plastic pipes are not perfect for the transportation of drinking water, so opt for polybutylene or CPVC. The chlorinated film resists heat and the growth of bacteria that ensures safe water reaches home.

Lightweight

One of the drawbacks of metal pipe is, it is heavy to carry and install. The biggest difference you can experience while shifting from metal pipes to PVC pipes fitting is it weighs ten times lighter than metal or steel pipes. Moreover, replacing metal pipes is a costly operation and requires more effort than PVC pipes.

Durability

If you are wondering will the PVC pipe fitting would be good for home, then fret not most of the PVC pipes have over 100 years of life expectancy. The plastic pipes can withstand environmental change, physical change, and weather changes. It does not succumb to corrosion like metal pipes. This is what makes them durable than metal pipes.

Cost-Efficient

PVC pipes are cost-efficient than metal pipes. The metal pipes are galvanized pipes which are expensive. The cost to purchase, install, and maintain is significantly lower than any metal pipe. The HDPE pipe suppliers recommend plastic pipes for home and office, as it lowers the total cost of plumbing compared to metal pipes.

Environment Friendly

Polymer is a low-carbon plastic, which means it has fewer adverse effects on the environment. It does not produce any toxic by-products and these are recyclable. The polymer pipes are easy to melt, and they can be made into different plastic products again and again. Whereas the metal pipes are disregarded when they get damaged.

Conclusion

Plastic pipes are the future of plumbing, due to their irreplaceable advantages. So, if you are renovating the plumbing system ask for the finest quality Utkarsh plastic pipes from HDPE pipe suppliers and make a significant change in your home's plumbing.

What Are The Different Agricultural Pipes Used For Water Supply?

India's economy largely depends on the agricultural sector and its allied industries. In agricultural fields, the crop yield depends on irrigation. To keep water transportation smooth in the fields for the cultivation of vegetables, fruits, and cereals, pipes play a crucial part. The popular pipes used for agricultural uses are agricultural PVC pipes, UPVC pipes, HDPE sprinkler pipes, and column riser pipes.

These pipes have a wide range of benefits, it resists corrosion, weigh a fraction of metal pipes, and are durable. Today we will discuss each of the pipes which are commonly used for agricultural purposes, so you can pick the one that fits your needs.

The Types Of Material In Irrigation Pipes Are

Polyvinyl Chloride (PVC) Pipes :

Polyvinyl Chloride Pipes have robust built which can withstand strong pressure flow from the pipes. These pipe casings are used for agricultural pipes and fittings to pull out water from the borewells. These pipes are not resistant to UV rays, which is why PVC is mostly buried inside the ground.

HDPE Pipes :

HDPE Pipes are known for their lighter weight, flexibility, and reliability and come with unmatched corrosion and chemical resistance. These pipes are commonly installed in the fields for free flow line irrigation, sprinkle irrigation, drip irrigation. Apart from irrigation, these pipes are also known for their usage in pesticide spraying systems and connecting water mains to the crop fields.

Column Riser Pipes :

Column Riser Pipes popularly known as Column Pipes are long tubes of various diameters commonly used for water lifting and connected to a submersible pump for agricultural irrigation. The prime features of Column Pipes are that they are durable, lightweight, and their interior is designed to be smooth to avoid the accumulation of residue and ensure the free flow of water.

Why Are Agricultural PVC Pipes Perfect For Irrigation Applications?

• Lightweight: The PVC pipes weigh the fraction of metal pipes. Hence, these are easy to transport and install. This reduces the time and energy for installation.

• Durable: PVC pipes are durable, it has a longer life span than metal pipes which makes them n deal choice for agricultural pipes and fittings. If maintained the PVC pipes can last more than 50 years.

• Cost-effective: Compared to metal pipes, these are significantly cheaper. From a farming perspective, it is quite economical.

You May Like: Agricultural Applications Of PVC Pipes

Conclusion

To sum it up, agriculture depends on a good water supply. A good irrigation system ensures a good yield. Utkarsh pipes are most favored for irrigation systems in India by agriculturists for their highly efficient and low-maintenance pipes.

Utkarsh India Limited is one of the best PVC pipes and fittings companies in India. They make agricultural PVC pipes from high-quality PVC compounds which are appropriate for extracting clean water from deep and shallow bore wells.

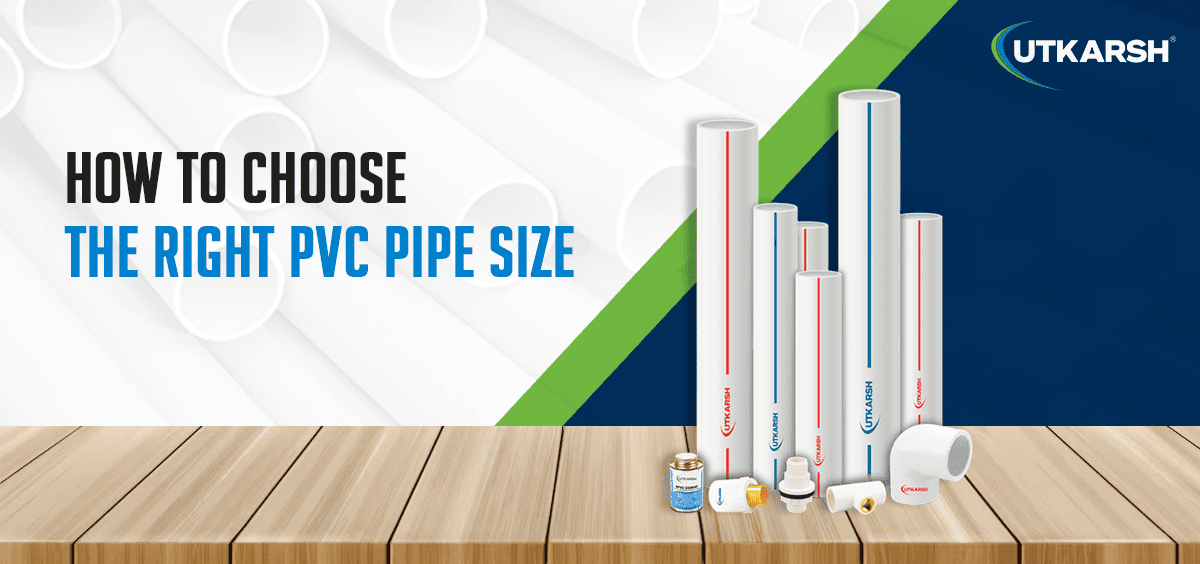

Choosing The Right Pipe For Your Applications

Selecting pipe is a laborious task and it can get overwhelming with so many options available in the market. Each piping material has different strengths and weaknesses and to choose the right one you need to understand its application.

The most common plastic pipes are PVC, CPVC and UPVC. Here are in detail description of each three so you can pick the right one for all your needs.

PVC Pipes

Polyvinyl chloride (PVC) pipes are probably the most common term when we think about pipes. These pipes are ideal for drainage application in residential properties. They can withstand high pressure that's why these are perfect for the main water supply. The PVC pipes can be used for both hot water and cold water supply lines. The PVC pipes are strong, durable, low maintenance and economical.

Common Application Of PVC Pipes:

• Drainage Lines

• High-pressure applications

• Main water supply lines

Utkarsh India manufactures PVC Casing Pipes & Ribbed Strainers from the high-quality compound and is appropriate for extracting clean water from deep and shallow bore wells which are among the best PVC pipes available.

CPVC Pipes

Chlorinated polyvinyl chloride (CPVC) is a thermoplastic produced by chlorination of polyvinyl chloride (PVC) resin used for hot and cold-water lines. CPVC pipes are heat resistant, they are known as high-temperature pipe materials. CPVC pipes are inherently chemical resistant that makes it suitable for wide range of industrial and commercial application.

Common Application Of CPVC Pipes:

• Drainage lines

• Hot water and drinking water lines

You May Like: Here Are Some Tips To Help You Choose The Best Pipe Suppliers

UPVC Pipes

Un-plasticized Polyvinyl chloride (uPVC) pipes lie between PVC and CPVC pipes when it comes to heat resistance. Their biggest benefit is that they are non-reactive. They do not react with the flow inside. This makes them the ideal choice for factories where chemical needs to be moved and where the chemical mustn't react with the material of the pipe. This makes it an ideal choice for factories. These are non-corrosive, so it is helpful in the passing of materials such as crude oil, seawater, and other acidic liquids.

Common Application Of UPVC Pipes:

• Irrigation projects

• Tap water

• Infusion pipes in the chemical industry

• Rainwater

To sum up, it is essential to understand the virtues that different pipes have as a result of their materials. It is wise to correctly understand and correlate these virtues to your requirements before choosing the pipe that will stay and act as the invisible force behind your water supply.

As a leading pipe company in India, Utkarsh India manufactures uFLO - "Lead Free" UV Resistant UPVC Pipes & Fittings, making it the most convenient, suitable, and cost-friendly solution for cold-water transportation. uFLO uPVC is manufactured with the best sourced raw materials and adapted to international standards. Water fitting pipes are Easy Installation, Light Weight to Carry, Optimum Flow Rate with Minimum Clogging.

Facts Regarding HDPE That Are Not True

High-density polyethene (HDPE) is a material that goes into the manufacturing of pipes that are perfect for outdoor and underground. The usage of HDPE pipes is comparatively new yet fast-growing. Consumers are replacing steel, ductile iron, and concrete pipe solutions after testing the efficiency of an HDPE pipe.

Busting Myths Related to HDPE Pipes

The following points aim to bust myths surrounding this piping material that still leaves scepticism among consumers. Once you clarify these doubts, you will be ready to purchase premium quality products from the best HDPE pipe suppliers.

1. Mechanical Joints Cannot be Buried

The primary myth concerning mechanical joints is that it does not work as good as fused joints when underground. However, the truth is, mechanical joints used for HDPE pipes are designed after considering buried services to make it sustainable for the underground environment. Mechanical joints are constructed with durable ductile iron housings and the hardware is coated with a fluoropolymer. The couplings remain non-destructive under a tough underground environment. Moreover, if there is additional protection required as per the property owner or engineer’s suggestion, additional coating can be provided.

2. Fusing Makes Joints Stronger

For decades, fusion has been a common approach to retain strength and durability. However, records state that weather conditions, temperature, and other relative environmental changes can impact this. If you appoint technicians to follow up on its progress meticulously, you will have a continuous inspection strategy. However, this method is costly due to such professional expertise. To eliminate the need to have a team of professionals monitor the fusion constantly, one must choose an effective alternative. HDPE pipes manufactured by Utkarsh India exceed pressure ratings, bend radius, and the tensile load of fused joints. Enabling it to be pulled, pushed, and dragged like a fusion solution.

You May Like: Uses And Advantages of HDPE Pipes

3. Cut a Groove is a Disadvantage

Many customers enquire HDPE pipe manufacturers if cutting a groove is a disadvantage and weakens pipe efficiency. Utkarsh India ensures that every pipe size has customized grooving tools to control them. Joints are designed to fill the groove with keys on the coupling’s metal housing. An iron ring helps lock the reduced wall thickness to keep it intact. Thus, it adds strength, which is completely reverse to this myth.

4. Fusing is Quicker

While many consumers have been following fusing for years, they can't help but admit that it is time-consuming. From weather conditions to terrain instability, multiple reasons make fusing challenging, time-consuming, and labour intensive.HDPE pipes are much more efficient to use, quick to install, and comparatively cheaper in terms of labour cost. Moreover, it is not affected due to changes in the weather, tight spaces, and challenging terrains.

5. Mechanical Solutions are Costly

HDPE pipes by Utkarsh India does not require high acquisition cost or maintenance. Mechanical tools are quicker to join and easy to install. These projects require much less labour cost or manhours.

You May Like: Factors To Consider When Looking For HDPE Pipes

Final thoughts

Utkarsh India is leading the way to amplify the usage of HDPE pipes because it is durable, convenient, cheaper, and sustainable. As you are now clear about the misconceptions and know more about the efficiency, you can rely on the best HDPE pipe products.

Advantages Of Using UPVC Pipes At Home Or Office

UPVC pipes serve as a low-cost plumbing material when it comes to building an office or home. It is a material known to have a high tensile and impact strength, making it sturdier and giving it longevity. UPVC pipes are used for the distribution of water in bathrooms, kitchens, overhead tanks and tube wells located in housing complexes and office buildings. UPVC stands for Unplasticized Polyvinyl Chloride, which makes it a low maintenance material, hence it is one of the most widely used materials for plumbing construction.

When should you use UPVC Pipes?

UPVC pipes are used for water distribution when it comes to plumbing construction and can be used for domestic purposes as well as commercial purposes. The best part about UPVC is that it has low maintenance requirements and does not require any sort of painting or sealing during its lifetime. It does not rust or corrode easily, making it a very strong material for water distribution systems like overhead tanks, underground tanks and tube wells.

When it comes to making a decision that is the best for your home or office it is advisable to look for materials that fit in your budget, is of the best quality, gives high durability and reduce the hassle of regular maintenance.

You May Like: What Are The Different Applications And Benefits of UPVC Pipes and Fittings?

What are the advantages of using UPVC pipes at home or office?

UPVC pipes come with a host of advantages, which is why they have become the gold standard when it comes to plumbing work. Let us now take a look at some of the advantages of using UPVC pipes at home or office.

Leak-resistant

One of the factors that make UPVC pipes an absolute favourite is that it requires zero metalwork for welding when it comes to their joints. UPVC pipes are available in various lengths, which makes it easier to avoid or minimise joints, that can later become potential points of leakage. Most joints that are required in UPVC pipes can be sealed with solvent cement.

Cost-effective

UPVC pipes are lightweight and cost-effective. They are easier to transport, handle and install, as compared to metal pipes. Thus, further reducing the cost implications.

Maximum water flow

UPVC pipes come with a smoothened inside surface that allows the flow of water through them to be at its maximum speed. This ensures the free flow of water, guaranteeing a smooth supply.

Durability and strength

With a high tensile and impact strength, UPVC pipes are known to last longer, have excellent bendability, be rustproof and are UV resistant which gives them long-lasting shelf life. Its flexibility also allows it to be one of the easiest to handle materials during construction.

Non-toxic material

When it comes to installing pipes for water usage, one factor that comes into the minds of users is the toxicity of the material. In other words, will the material leach toxic components into the water. Given the make of the pipes, they are non-toxic and non-reactive, making them a safe option for plumping in homes and offices.

These are some advantages of using UPVC pipes, to consider when you are building your home or office space. Check out Utkarsh India’s offerings in UPVC pipes category to find the right fit.

Things To Keep In Mind When Choosing A Home Drainage Pipe Solution

The advantage of indoor plumbing is it effortlessly flushes out the water of your home. But, that pipeline is not a one-way street and any damage in a pipe can whiplash back drain water into your home. This leads to various problems, not only unpleasant odors but also has health risks associated with that. To prevent this from happening it is important to choose the right drainage pipe for your home.

After all, no one enjoys a plumbing disaster. Being one of the leading names in the plumbing industry, Utkarsh India manufactures high-quality sewer pipes in India. We recommend PVC pipes, galvanized pipes, and SWR pipes and fittings. Read along to know how to prevent mishappening, by considering a few factors while choosing a home drainage pipes.

Be Aware Of The WaterType

The water flowing in your homes is the same that goes back in the drainage system. The water supply in many areas of our country is corrosive. The hard water contains an excess amount of minerals like magnesium or calcium which accumulates in the piping system. It hampers the flow of the water, which leads to clogging or disruption in the proper drainage of water.

Therefore, to reduce the impact of hard water on the pipe fittings, you must choose a pipe that remains unaffected by the quality of water flowing through the pipes.

Plumbing Use

The pressure of water differs on different nozzles. The pressure of water is different for the bathroom compared to the kitchen. The pipes in the washroom have curves or bending compared to kitchen pipes. This is why it is important to consider the location for which the pipe is installed this reduces the risk of clogging in the home.

Check The Quality

One of the factors that should not go unnoticed is checking the quality of the pipes. Before selecting any pipe for the drainage system look for credentials like ISO, ISI, ASTM. BAS for ensuring the quality of the pipes.

Look For Professional Plumber

While buying a pipe is in your hands, but installation is not. This is why, while considering a proper drainage system in any home, look for professionals who know how to properly fix your toilets.

You May Like: Plastic Plumbing Pipes - Why Are They Better Than Metal Pipes?

Types Of Pipes For Proper Drainage Solution

In simple terms, a drainage pipe helps in the removal of water from a particular area. Types of drainage pipes include road drainage, municipal drainage, rainwater drainage, house drainage, building, and industrial drainage.

Not all pipes solve the same problem, different pipes are installed for serving different purposes. Here are the types of pipes for proper drainage solutions.

PVC Drainage Pipes

PVC is the most viable option when it comes to water drainage. They make up almost 75% of wastewater sections. As these pies are installed with solvent cement and rubber ring, the pipes are an affordable and time-saving solution.

SWR Pipes And Fittings

SWR is the acronym for soil, waste, and rainwater solution. This helps in managing rainwater drainage and building drainage in the home. SWR pipes and fittings is mostly used for exterior water drainage.

Conclusion

Pipes are crucial for any home. Proper drainage reduces the risk of mold or damage to the home. We at Utkarsh, provide high-quality plastic pipes and GI pipes which are most commonly used for plumbing.

Applications Of HDPE In Different Industries

HDPE pipes are High-Density Polyethylene pipes that are more flexible than other plastic pipes and help in the traverse of fluids for industrial and commercial purposes. The high-density polyethylene has a strong molecular bond that improves stress impact and tensile strength of the pipes making it suitable for high-pressure pipelines. It is often used as a replacement for concrete pipes and steel pipes.

Utkarsh manufactures HDPE pipes from PE products available in sizes from 20mm to 315mm in PE 63, PE 80 & PE 100 grades conforming to national & international. These pipes are effortlessly used in numerous applications.

Why HDPE Pipes?

Before we delve into the applications of HDPE pipes it is important to know about the benefits that make them suitable for those applications. HDPE pipes have high tensile strength, lightweight and durable.

The pipes are resistant to microbial attack, corrosion from corrosive substances like acid, base, and salts. Furthermore, require fewer fittings and can be welded into seamless leak-free pipes. Owing to these advantages, HDPE pipes are used in an array of applications.

Application of HDPE Pipes

Agriculture

India is an agrarian country and to ensure effective transportation of water in the crop field, HDPE pipes are used. It is largely used in the agricultural industry for flow line irrigation, tube well pipes, drip irrigation, and pesticide spraying system. Food-grade polyethylene virgin material is used during the manufacturing process of HDPE pipes, this is why these pipes are safe for the supply of water to crop fields.

Industrial Uses

These pipes not only carry fluid of any kind from one point to another, but it is also corrosion and abrasion-resistant making them a better choice for passing effluents, acids, alkalis, and slurry in industries. Properties like corrosion resistance, impact resistance, flexibility, resistance to chemical contamination, and slow crack growth make it suitable for fluid and gas piping systems in industries.

Industries that are predominantly using HDPE pipes are the fertilizer, pulp, and papermaking industry, power plants, petrochemical, glass, plastic resin manufacturers, and many more.

You May Like: Facts Regarding HDPE That Are Not True

Submarine and Underwater Pipeline

These pipes are joined by welding. Butt welding, electrofusion, and socket welding are some of the methods of joining HDPE pipes. As these pipes do not need anchors or thrust restraints for joining, these pipes are better for underwater applications. These pipes do not react with salt water, or industrial effluents which is why it is used in submarines and underwater pipelines.

Portable Water Disposal

While renewing the existing pipeline, there is enough evidence that supports using HDPE pipes reduces expenditure and installation time. These pipes are used in sewers, drinking lines, and main drinking lines. The pipes have a low friction coefficient and low flow resistance, ensuring resistance free-flow from the pipes. It is safe to use between temperature -220 degrees Fahrenheit to 180 degrees Fahrenheit.

Conclusion

Utkarsh India Limited is one of the leading HDPE pipe suppliers. These pipes are effective for fluid transfer for aboveground, underground, or even in floating applications. The usage of HDPE pipes ranges from industries to commercial water supply.

Utkarsh's Polyethylene HDPE pipe is strong, extremely tough, and very durable. Whether one is looking for long service, trouble-free installation, flexibility, resistance to chemicals, or a myriad of other features, polyethylene pipe will meet all the requirements.

What Are The Advantages Of UPVC Pipe?

When it comes to choosing a pipe for domestic, commercial, or industrial purposes, plastic pipes are known for durability. The plastic pipes which are commonly used for industrial and residential purposes are PVC, HDPE, UPVC, and CPVC pipes. Out of them, today we will discuss the advantages of u-PVC pipes to understand why it is preferred over PVC and CPVC pipes.

What are UPVC pipes?

U-PVC pipes stand for unplasticized polyvinyl chloride pipes. These pipes are enormously used in buildings, for the supply of potable water. As the pipes do not contain BPA or phthalates, it is sturdier than PVC pipes. These pipes are not only used in bathroom and kitchen sinks, these are also used in industries for fulfilling the supply and demand of industrial effluents.

Advantages of uPVC Pipes

Durability

If you have ever seen someone living with leaky pipes, you would know how difficult it is to stay in moist or wet spaces. This is why choosing a pipe that has better durability is important in long run. uPVC pipes and fittings have higher tensile and impact strength that enhances their durability making them a long-lasting solution for all plumbing needs.

Non-toxic

These pipes are BFA free as mentioned above, which makes them completely safe for transporting drinking water. Needless to say, these pipes are safe to use in the health and hospitability business as these pipes do not carry contaminated water.

At Utkarsh India, we have uFLO-"Lead-free" UV resistant UPVC pipes that do not contaminate the liquid flowing from the pipes. This ensures fluids like industry effluents or water do not get contaminated when flowing through the pipes and ensure your water do not contain carcegonic compound like Lead.

Non-combustible, Better Fire-safety

When it comes to thinking about fire hazards, plumbing is the last thing one considers. Albeit plumbing does not help in initiating a fire, however, fires can start during maintenance or installation of new pipes, when plumbers perform soldering work. To avoid unwanted fire breakout, UPVC is the right fit for the home. It is a self-extinguishing material, it does not promote fire.

Leak-Resistance

The UPVC pipes are available in a range of sizes, this reduces the number of joints in the pipes, hence reducing the risk of leakage in the pipes. Furthermore, the pipes are joint with solvent instead of soldering or metalwork that keeps the risk of leak to a minimum.

These pipes do not shrink or break due to hot water or cold water. The pipes can withstand up to 93 degrees which makes them suitable for both hot and cold water.

Easy To Install

These pipes can be easily installed with a few simple steps. With the help of solvent and cementing, the pipes are chemically fused. When the pipes coalesce together, it forms a strong bond that enhances the strength and durability of the pipe. In addition to that, the pipes are light in weight and do not require any electricity during installation, which is helpful for areas with no electricity connections.

Hassle-Free Maintenance

Changing or repairing a pipe, again and again, is not one dream of while choosing a pipe. This is what, Utkarsh India thrives by, to provide a pipe that does not need maintenance in years. UPVC pipes are resistant to chemicals or rusting, it does not break or leak. It can withstand the change in temperature, which makes it hassle-free to maintain. Furthermore, these pipes are not prone to scaling, this means they do not require frequent cleaning making them easier to maintain.

You May Like: Advantages Of Using UPVC Pipes At Home Or Office

Conclusion

UPVC pipes are the new piping material that makes plumbing easy to maintain. Utkarsh India Limited's UPVC pipes are available in sizes of 1/21â„2 to 2", as per ASTM D 1785 Schedule 40 and 80.

Incorporate uPVC pipes and fittings in residential plumbing, swimming pools, industrial process lines, saltwater lines, and chemical sector with Utkarsh India limited.

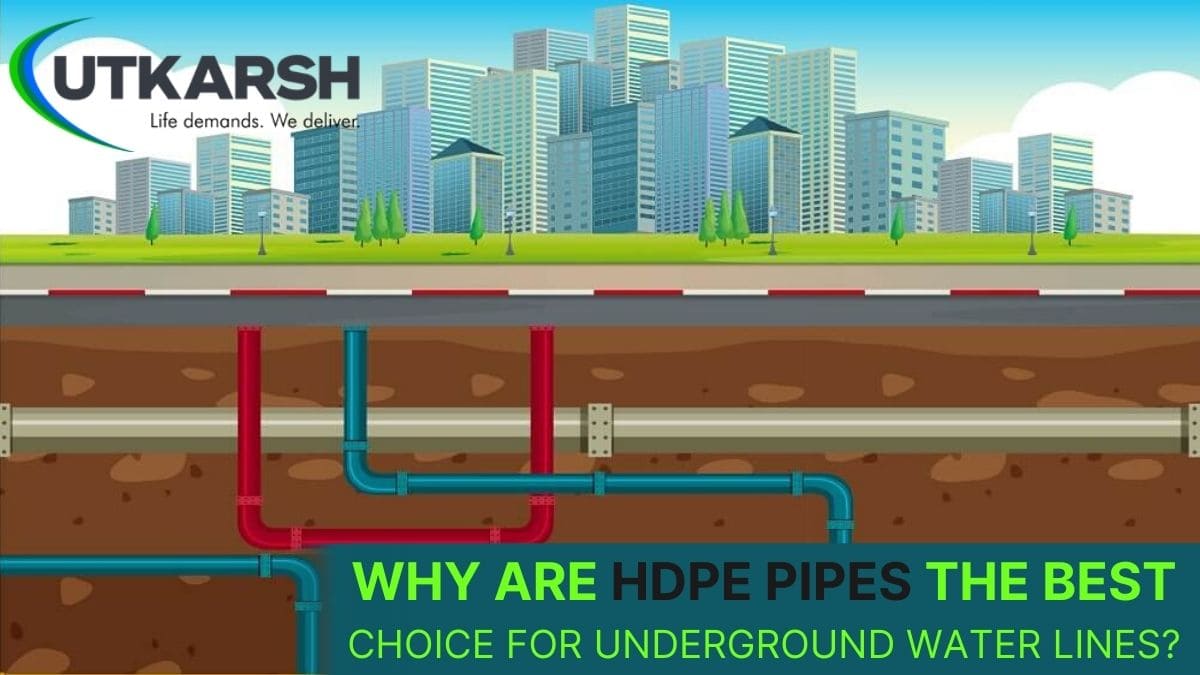

Why Are HDPE Pipes The Best Choice For Underground Water Lines?

If you want to replace old water utility pipes, the most reliable option is HDPE pipes. Earlier, metal pipes were more commonly used. However, they are prone to deteriorate comparatively quicker. Moreover, when comparing aspects like durability, prices, and generic features, HDPE pipes are much more efficient.

Reasons to Choose HDPE Pipes for Underground Water Lines

High-density polyethene pipes are strong, durable, and light. They are also cost-effective because installing them can give you an expected life of 50 to 100 years.

The followings points suggest why you should consider choosing HDPE pipes for underground water lines:

Durable

Many types of plastic pipes are prone to breakage. However, HDPE pipes have longer coils or sticks, making manufacturing easier and the product durable. Since it requires a lesser connection between pieces during the process of thermal fusion, it reduces time consumption, making it less labour intensive. Moreover, the process of installation is easy and efficient.

Sturdy and Light

While HDPE pipes weigh lighter, the material is much stronger. Since the weight of the products is light, they are easy to manoeuvre. Moreover, it easily fits into tough soil conditions making it easily usable in several regions. Thus, if you fail to install other types of pipes on a particular ground, HDPE pipes will resolve it for you. .

Leak Proof